Electronics molding – experience it up close in 2023

24.Jan 2023Live and always with the latest news, we present the Low Pressure Molding technology for electronics molding every year at various events.

Both at trade fairs and in talks at workshops, congresses and symposia with different industry focuses, we show the process and equipment in detail and offer individual exchange on the requirements in a wide variety of applications.

We have already planned the following dates for 2023:

- Henkel AEI Electro Days – Expert Talks LPM March 13th in Düsseldorf

- Smans NV Cable and Wire Inhouse Show March 14th – 16th in Turnhout BE Smans | Cable & Wire In-house Show 2023

- Kuteno May 9 th – 11 th in Rheda-Wiedenbrück - KUTENO

- Productronica November 14 th –17 th in Munich productronica | Trade fair electronics development production

… further events will follow.

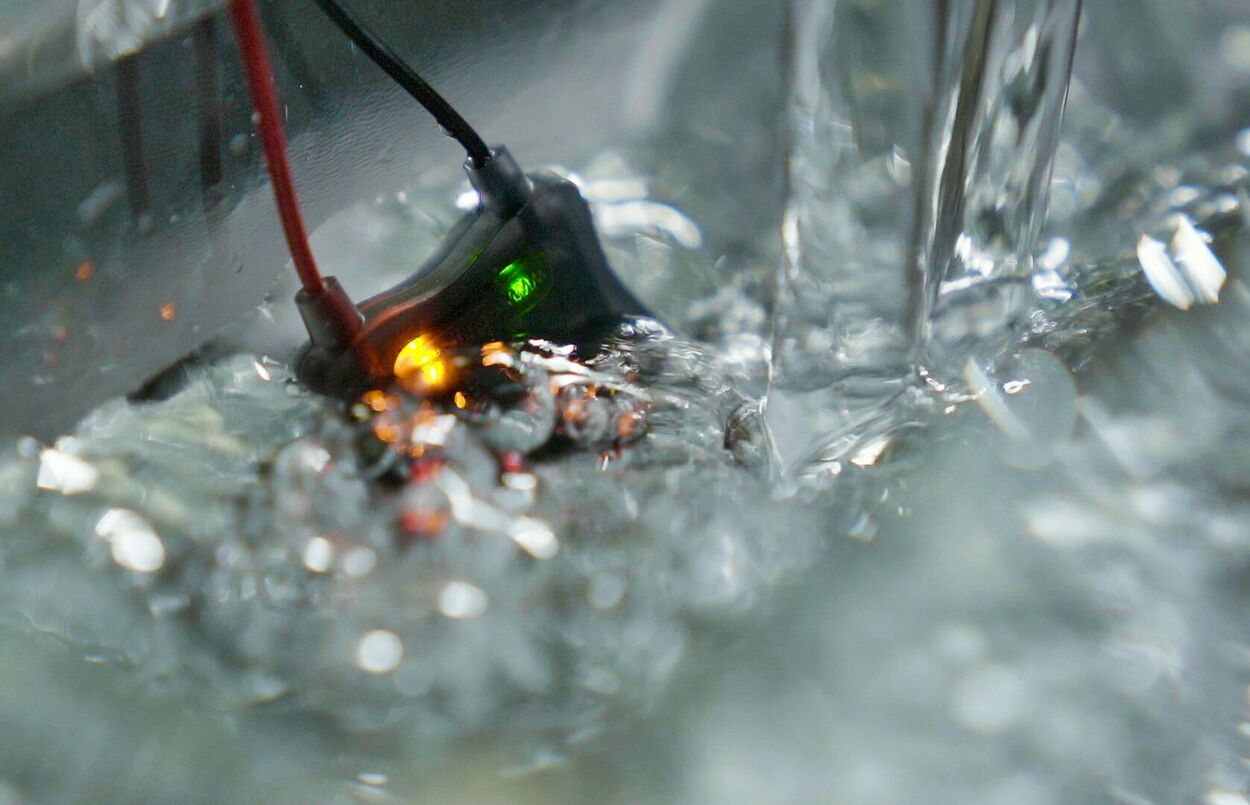

Low Pressure Molding (LPM) is a process for electronics molding, means protection of electrical and electronic components (such as printed circuit boards or sensors) against vibrations and shocks. LPM insulates against heat, cold, moisture, weather in general and electrical energy. The design is space-saving, cost-effective and individually designable.

Thermoplastic hot melt adhesives are used as molding compounds. The predominantly pollutant-free materials based on dimer fatty acids are liquefied by heating. They can be introduced into moulds at low pressures and solidify when cooled.

Against the backdrop of increasingly compressed installation space and growing power densities, the demands on the design of electric and electronic components are rising. Encapsulation processes and materials are among the decisive factors for the durability of electrical and electronic assemblies.

Originally developed for and in collaboration with the automotive industry, the process has now become an established manufacturing technology in many areas of electronics production and is used in various industries.

You can also find more information in our detailed white paper: